Industry news

Real Truth Why Making Textiles in the United States More Expensive Than In China

Textile manufacturing, as a labor-intensive industry, has helped many developing countries achieve economic growth and accumulation in the early stages of economic development. Japan, South Korea and China are typical examples.

For China, though, its demographic dividend is fading, and many of its textile manufacturers have shifted much of their manufacturing base to cheaper Southeast Asian countries, like Vietnam, Myanmar, Cambodia, Bangladesh and other countries. Considering the overall infrastructure level and workers' technical level in Southeast Asian countries, most of small and medium-sized manufacturer are not able to operate well in these regions.

Therefore, importing textile from China is still the primary option of most small and medium-sized importers in the United States. Trump's emphasis on bringing manufacturing back to the United States, and the fact that many Chinese textile manufacturers are starting to build factories in the United States, seem to give the impression that American manufacturing costs will be lower than that in China.

So let's tell you the differences between the cost of manufacturing in China and in the United States.

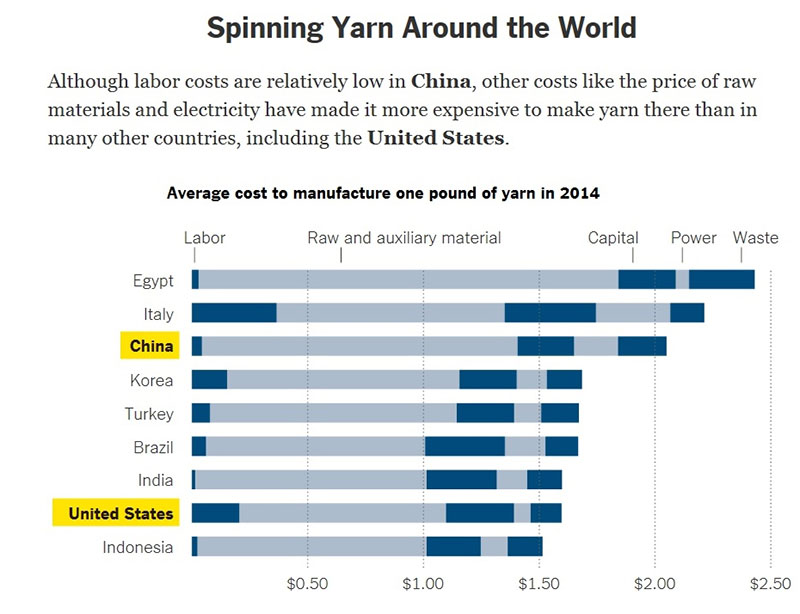

A New York Times article suggested in 2015 that “yarn production costs in China are now 30 percent higher than in the United States” because of savings in raw and auxiliary material. The article believes the cost difference is why some Chinese textile companies are coming to build factories in the United States.

However, from a interview with China Textile News, who provided a different cost sheet (as above). Reviewing it in detail, although setting up factory in United States may help save money in land, electricity, natural gas, and logistics, it will significantly increase the costs in purchasing manufacturing equipment, building factories and managing daily operation of the company. Additionally, due to strict labor policy in the United States, it could be critical challenges when competing with Chinese based factory.

News

CONTACT US

Name: Tim Tao

Mobile:+86-13912796617

Tel:+86-13912796617

Email:Admin@sunrisingtextile.com

Add:No.29 Nanhu Road, Zhangqiao, Xinzhuang, Changshu, Suzhou, Jiangsu, China ZIP#215000

Tim Tao

Tim Tao